Seal testing via thermal imaging is to be brought to market through a collaboration between Shemesh Automation and a team of dedicated engineers.

This breakthrough solution is a 100% reliable, non-intrusive method of testing which will revolutionise packaging lines for heat-sealed containers across a wide range of sectors.

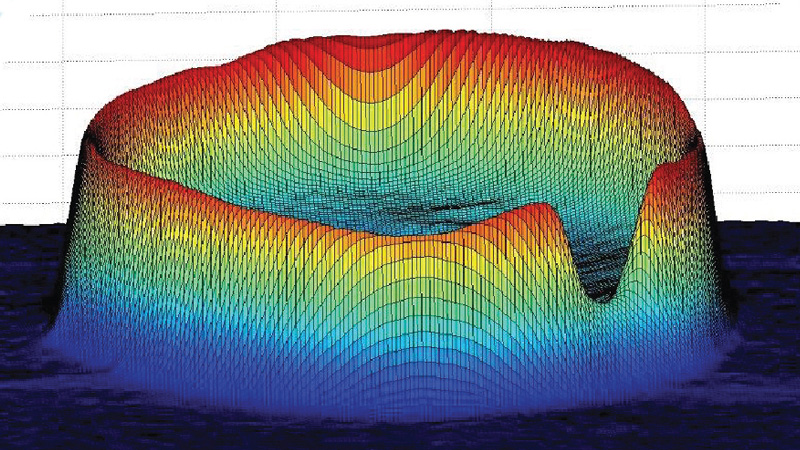

Until recently, thermal imaging has not been possible with heat-sealed containers because the imaging cameras were affected by residual heat. Engineers at Shemesh Automation are now hard at work incorporating this brand new solution into the Shemesh SealPro Total machine.

Alternative methods of heat seal testing are either physical sample checks or vacuum testing. Sample checks do not guarantee the quality of every seal and vacuum testing is intrusive, slowing down the production line.

Now, with thermal imaging incorporated in the SealPro Total, seal testing will become part of the production process; testing every unit and operating at the same speed as the packaging line itself. This linear, thermo-sealing work station automatically applies the seal, cuts the sealing material to shape and now tests the seal with 100% accuracy. Various options are available, with a capacity of between 20 and 200 units per minute.

By incorporating this technology into the SealPro Total, Shemesh Automation will now be the only manufacturer in the world to offer total Quality Controlled thermo-sealing machines.

Shemesh Automation, through this initiative, is the first company to apply highly sensitive thermal imaging technology to packaging.

Keep an eye on www.shemeshautomation.com for the latest developments on this revolutionary technology.